All methods of building have their place, whether it’s stick framing or timber, framing or straw bale or steel or concrete block.

Stick Frame

The advantage to a stick frame construction is that most of the construction industry knows how to build with individual pieces of lumber. Roofs, floor trusses are cut and then all pieces are nailed together and so mounting is, effectively done on the construction site from individual pieces of lumber. Once the frame is built lots of flat drywall surfaces are nailed down on the the frame to form the walls.

Most building contractors utilize this as their recommended way of constructing their houses given that they often tend to develop residences that are supposed to have unique, distinct architecture, but in fact today\’s architecture is so much alike.

- The biggest benefit of stick built home is that when builders come across a problem, they can quickly fix because it\’s easy to cut through the frame since it\’s built from sticks.

- There is also an understanding within the sector and the general public\’s mind that stick constructed homes have a higher level of quality and also that carpenters and framework teams that are building homes are much more skilled than any other builder.

Timber Framing

- There are so many fewer pieces. There’s considerably less wood total in a timber frame than there is in a stick frame.

- Today’s modern timber frame gets covered with SIP panels so that when you’re done, the entire frame is visible.

- The joy of cutting out a timber frame. We need just four simple frames that give you the whole structure. With SIP panels on the outside of the frame there is no conduction of heat from inside to outside.

- With the frame being inside, you have the joy of looking at the live wood that have been in your own forest. It’s also a lot more dampening of noise.

A very local difference between timber frame and a stick frame is that all of the materials can be coming from your own lot. If you had a tea trees available, all of them could be milled right on your site, and you would have a home that comes right from your own property.

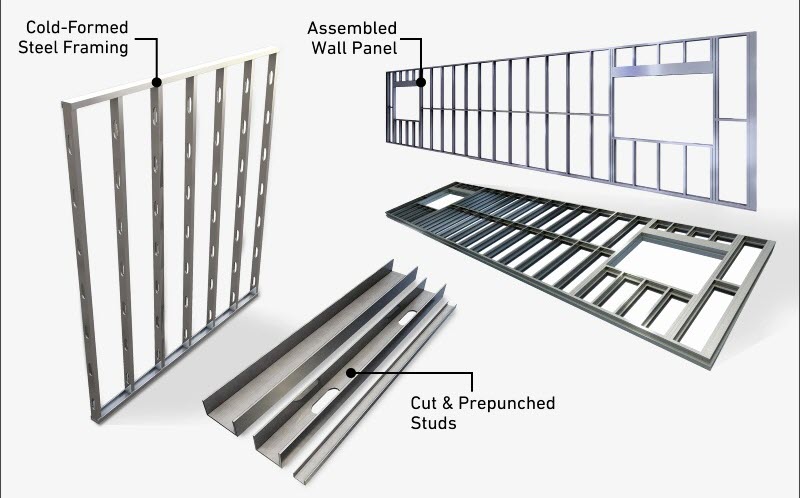

Metal Framing

What are metal studs?

There are different ideas around steel framing. Some people think of steel frame as of the red iron that is inside of big warehouse buildings or on structures high rises. Instead it is going to be like gauge steel framing. The material usually is thinner than 16 gauge, little bit thicker at times, but it’s lighter. It’s bent into a C channel shape that resembles a normal nominal stud like a 2/4 or 2/6 made with cheap metal.

Basically, those look like wooden studs except these are hollow and shaped like a C instead rectangle.

Steel Frame vs Wood Frame

There are three building modalities, stick frame that’s with wood, sips, which are the structural insulated panels and steel. The wood frame and steel frame are going to be built very similarly. Usually there is 16 -24 inch on center studs to allow our sheet material. The way that the stud is built there is space to insulate the channel inside of 3.5 inches cavity which sometimes is a 5.5 inches cavity so both of these are very similar in that regard.

The main difference for the naked eye is one a shiny steel and the other one is a wood. These look very similar as far as what has been involved in the makeup of the build.

Weight Difference

When building a tiny-house the foremost concern is of the weight difference. Wood Framing is of solid 2/4 rectangle. It’s taking up all of that space with material, so it’s a heavier product just in general. On the contrary steel stud is a thin sheet of metal bent into that same shape, mostly hollow space. So, we are looking at somewhere between anywhere from 40-60% lighter weight using the steel framing. That is just the weight of the framing, the entire weight depends on the complexity of the structure just like budgeting our money and time, we shall consider budgeting our weight because the tiny houses are governed by the weight of the weight rating of the trailer.

Strength

We are talking about a non-organic material, so the standard of its precision is lot higher than a wood material. If it\’s humid climate or not so humid climate, the steel is going to be the same material and is not at all affected by weather the same way of it is for woods. Another specific differences between steel versus wood is going to be strength, means pound for pound steel is 25 times a strong. There isn’t pound for pound because steel frame is much lighter weight so, we are looking at about a net gain of 10 times strength than wood.

Nail vs Screws

The only difference may be the transition from using a nail gun to a screw gun. In steel framing it is simply done using screws. There’s a great debate on the screws versus nails because people who do use screws, oftentimes just use box of deck screws that have a lot tensile strength but not sheer strength. There are so many different screws out there for different purposes. We may use eight different types of screws for various parts of the build. There are specific screws for sheeting that to provide more sheer strength. The long-winded argument that we hear a lot is how nails have always provided more sheer strength than screws which has been true. But later techniques and things that have come out now screws provide more pullout strength and is used as a method of fasting the process.

The Cost

Determining the cost could be tricky as if the price of just a wooden stud is considered the cost will definitely be less but with all the labor cost involved, it rises. The metal frame comes organized there is no need to find any other person to nail it or to shape the studs in a definite way. This way the price become comparable. For wood 60% of the cost on the labor force and 30% on materials, whereas a steel frame it’s about flipped. It’s closer to about 60% on the material costs and about 30% on the labor.

Are there benefits for metal Frames when it comes to insulation?

When spray foaming that that foam is actually able to go inside of those C shaped channels. There are some difficulties with the steel framing because of the channels especially in places where there’s really tight trusses or systems where there’s multiple angle pieces which are very close together. There\’s more opportunity for insulation in the cavity than there would be in a wood frame because you have all the space inside of those channels. The potential for energy to transfer through your steel frame to the inside of the house is known as thermal bridging. It may not have any kind of brake to stop the energy from the outside to transfer to the inside, this is going to be touch off an insulation. It doesn’t take much to heat or cool a space that small. the simple fix for thermal bridging is a continuous insulation layer on the exterior of the house. The one that\’s most known is the ZIP system. ZIP system has an R sheeting that provides 1/2 inch of foam on the back of it.

Metal has certainly the advantage on weight and strength and potentially the advantage on insulation

Metal vs SIP

SIP or structural insulated panel. This weight about the same or even a little more but have superior insulation. There are two different kinds of sips. Majority one is simply a piece of wood sheeting with a bunch of foam compressed in between it and another piece is of shooting on the exterior kind of foam sandwich. There are some steel sips as well. sip is anything because it\’s unique in the fact that it\’s providing you the structure as well as the insulation. All in one. A steel frame is going to be a lot more similar to a traditional building method which means there\’s more resource is out there for it. Though there is more flexibility using metals as you can just make a hole for wiring or to hang a shelf.

How Fasteners work in a Metal framed house?

It could be done with a strong enough magnet. We can find studs with magnet. As its steel, with strong enough magnet there should be no problem to find a stud. For an expensive thing, it would be wise to use screws instead of nails and would screw directly into a stud. The cool thing about the steel is its tensile strength. Using the right kind of screws after getting three pitches sunk into that steel frame a well, a good connection is established. Pull out is a big issue for a steel, with a magnitude of such massive strength nails could easily pull out. It is recommended to get a stud with a magnet, screw through it and hang the desired product.

Design Methodology

There are pros and cons to every single trailer. The easiest way to do it would be finding a trailer that allows for a perimeter. Fender walls are the main thing that gets on the way of structural design. For instance if there is an 8 feet by twenty feet trailer, that eight feet by twenty feet is required as a perimeter. The inner four inches or 3.5 inches to be a completely solid flat plate of material that could be drilled. A lot of trailers have a C channel flipped on its side where there is only 2 inches material. A 3.5 inch stud that sits on the outside perimeter of that two inches, it’s tough to find a center point that can be drilled through. For steel material it is necessary as the connection is to be made with a bolts unlike wood. Apart from this it us absolutely doable on other trailers too but would be just a big exercise.

Technology

It all starts on the CAD design program. They will draw the frame exactly how it\’s been specified by the customer, making sure that all the window openings and door openings are in the correct places and are the correct dimensions so that the provided the rough opening dimension slides right. Once the design is done and the 3D model is out. The 3D model is taken to the factory and is printed. The frame is printed from a massive coil of sheet metal. The penalized tool is attached with a screw and no special tools is required.

Shipping Containers

[embeddoc url=\”https://otinyhouse.com/wp-content/uploads/sites/7/2021/04/Sipping_Containers_For_Tiny_Houses.pdf\”]